SENSORICS

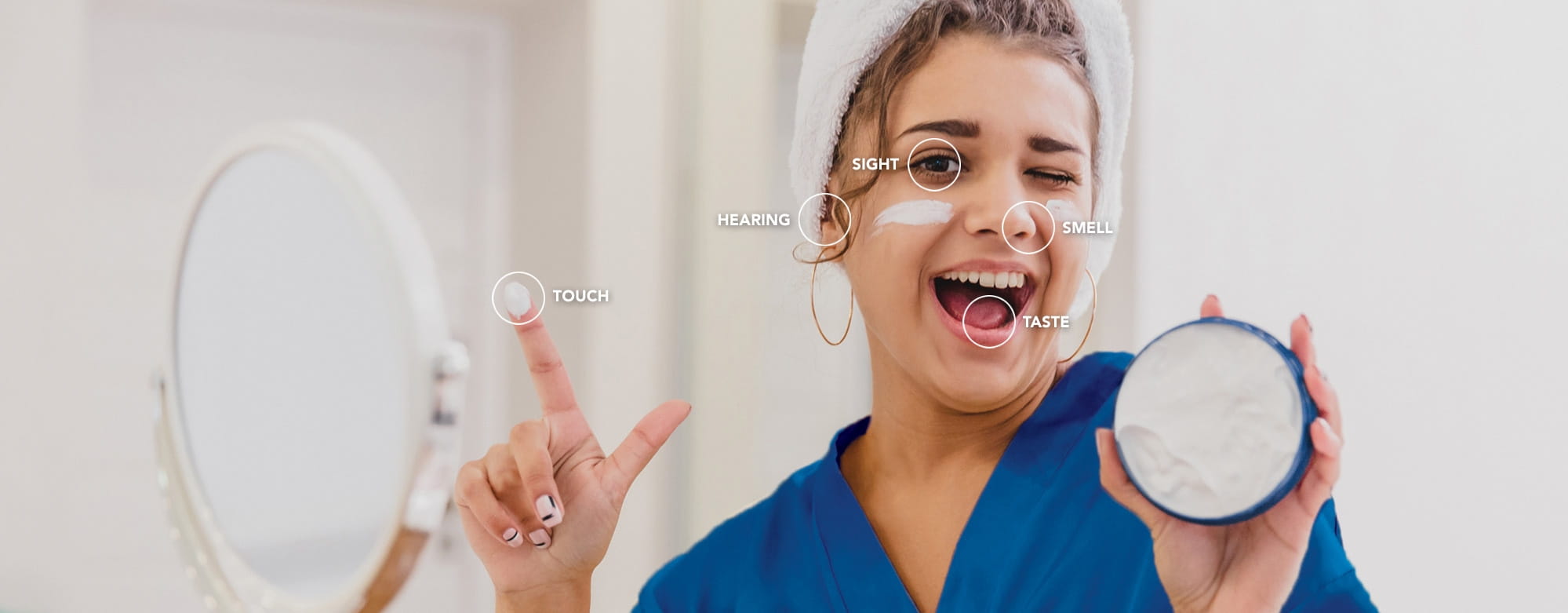

SENSORICS – Creating the perfect product with all your senses!

EXPERTS EXPLAIN

… what SENSORICS means to us

Sensorics is an interdisciplinary science that focuses on the perception, description, and evaluation of product properties using the five human senses: sight, smell, taste, hearing, and touch. The aim is to objectively capture and reproducibly describe sensory attributes.

In the cosmetics industry, sensory testing methods are an essential part of product development. They help assess how ingredients influence the perception of product properties and provide insights into consumer opinions — enabling targeted product improvements.

Both descriptive methods (e.g., profile analyses) and discriminative tests (e.g., difference testing) are used: